Optimised looks better

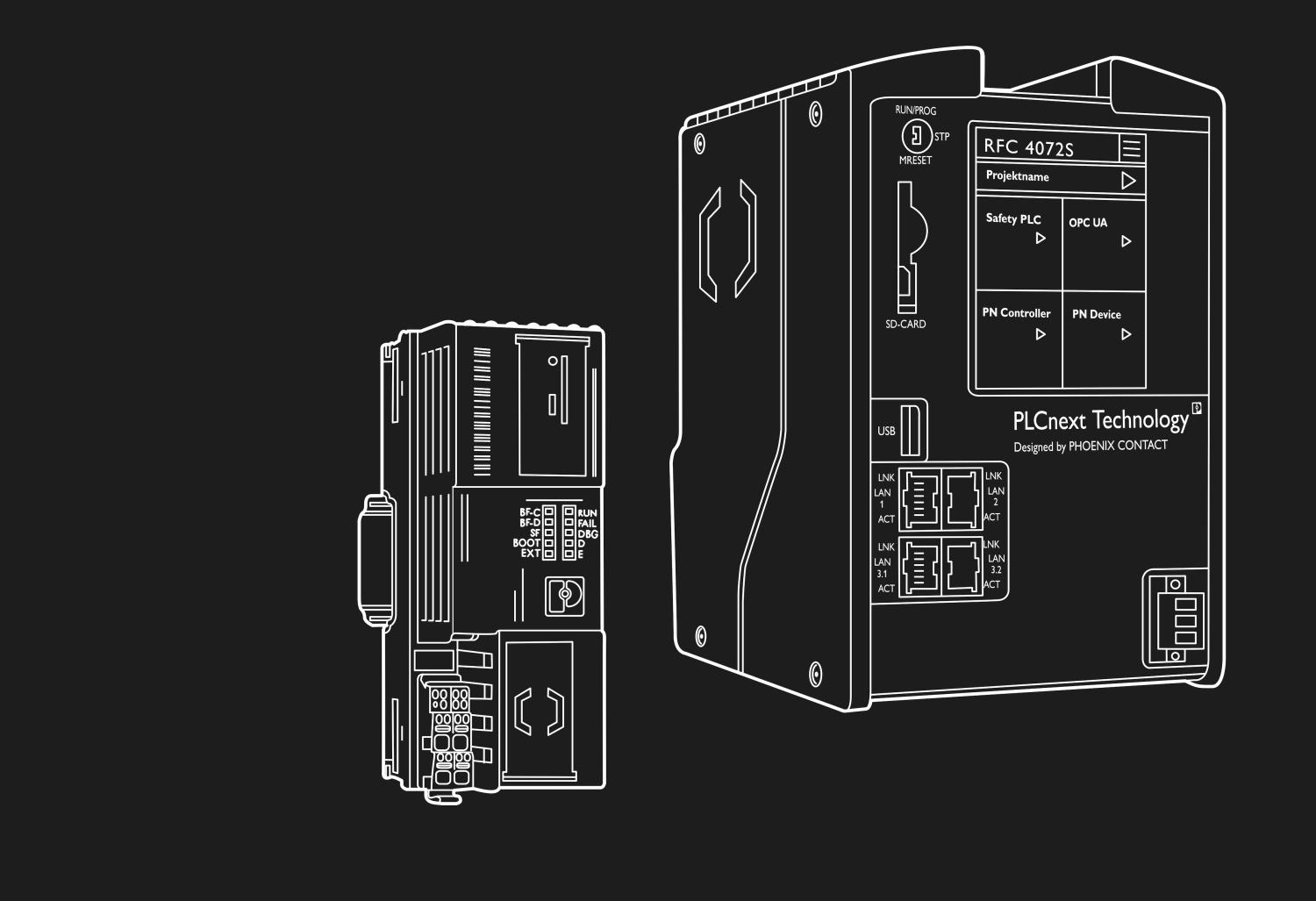

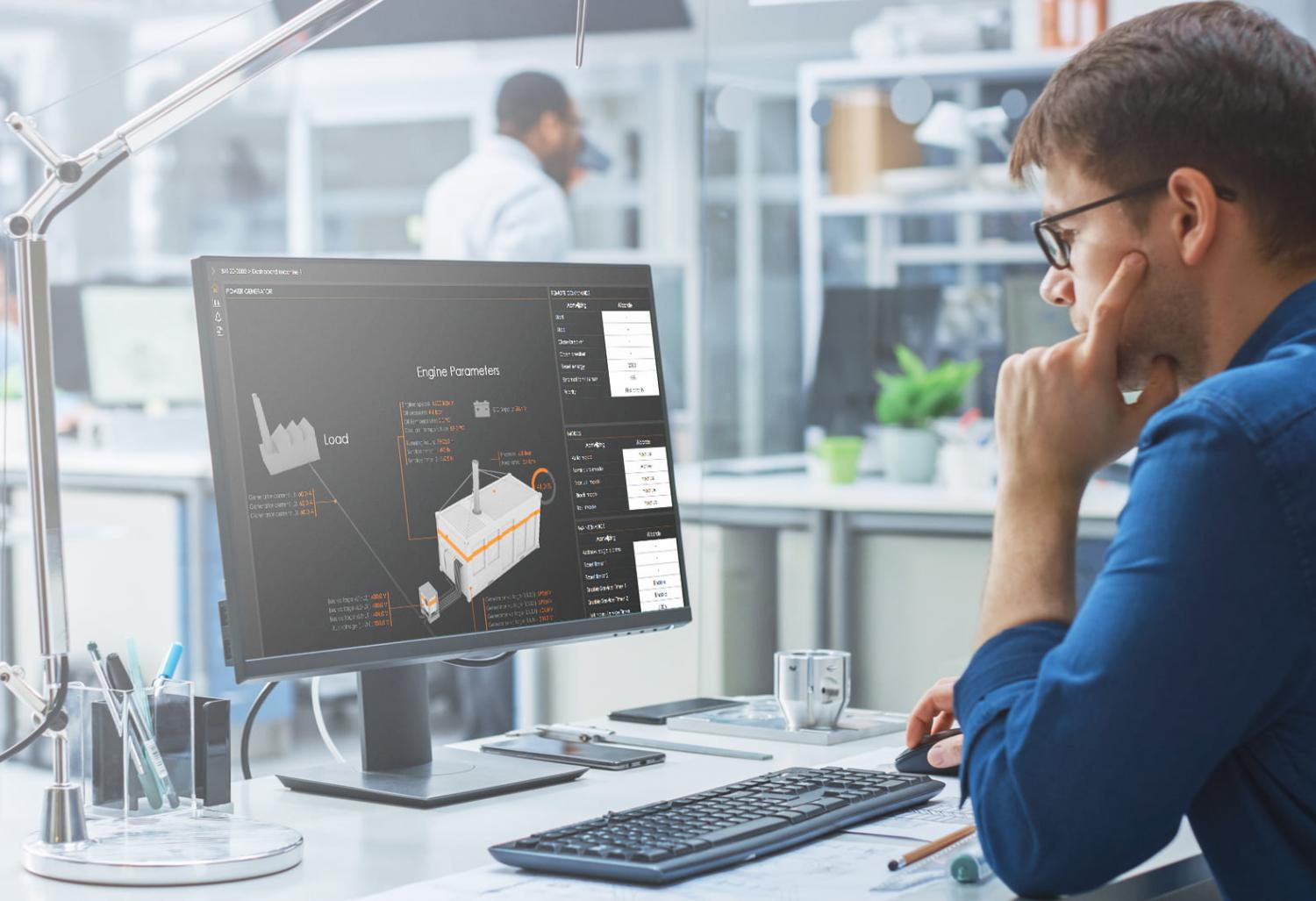

"The old installation is controlled by two obsolete TSX17 PLCs and two out-dated XBTA displays," explains Benoit Dery. The machine is more than 25 years old and with such an old-timer, any software change isn't without risk. For the displays, any update is simply out of the question. And yet, Arcsom was able to solve this issue. "After carefully backing everything up, we carried out a 1-to-1 conversion in the first phase and realised a short term modification with minimal down time. The integration of touch screen displays provides an overall upgrade in user-friendliness," says Benoit Dery. "In the second phase, the production process is optimised. The results are a better mixing of the three types of cheese and a simplified start-up procedure. We network all controls so that the production data is available to higher-level systems. This creates a clear path to collecting, processing, visualising and reporting."

An increased efficiency for Colruyt

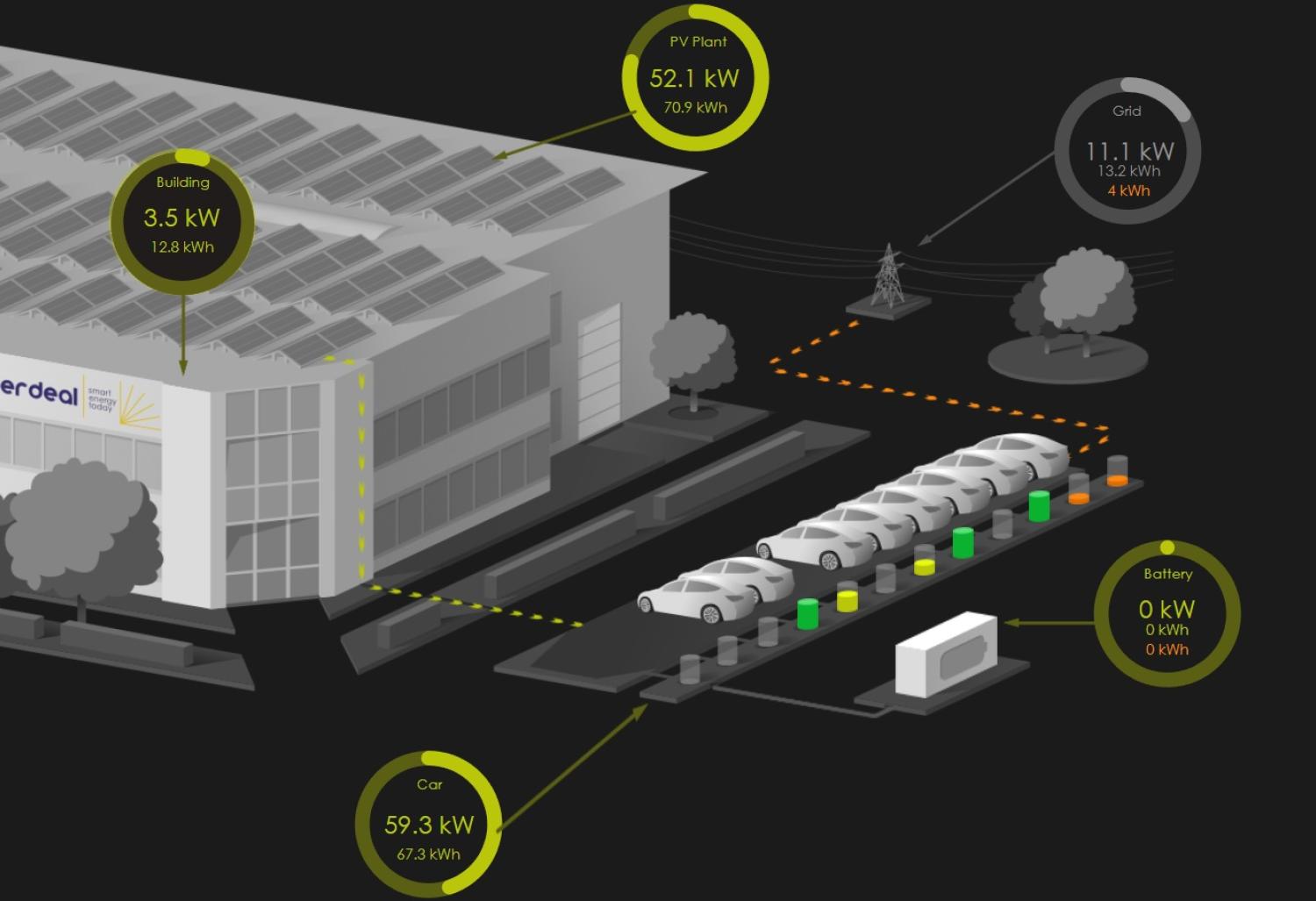

When Colruyt decides to embrace this optimisation and include the PLCs in its network, everything becomes more accessible. Additionally, the diagnostic possibilities are drastically improved and the intervention times in case of breakdowns are greatly reduced.

The upgrade of the cheese machine in Halle brings so many new possibilities. Would you like to know how Arcsom could easily optimise systems for your project? Book an expert session.