Challenge

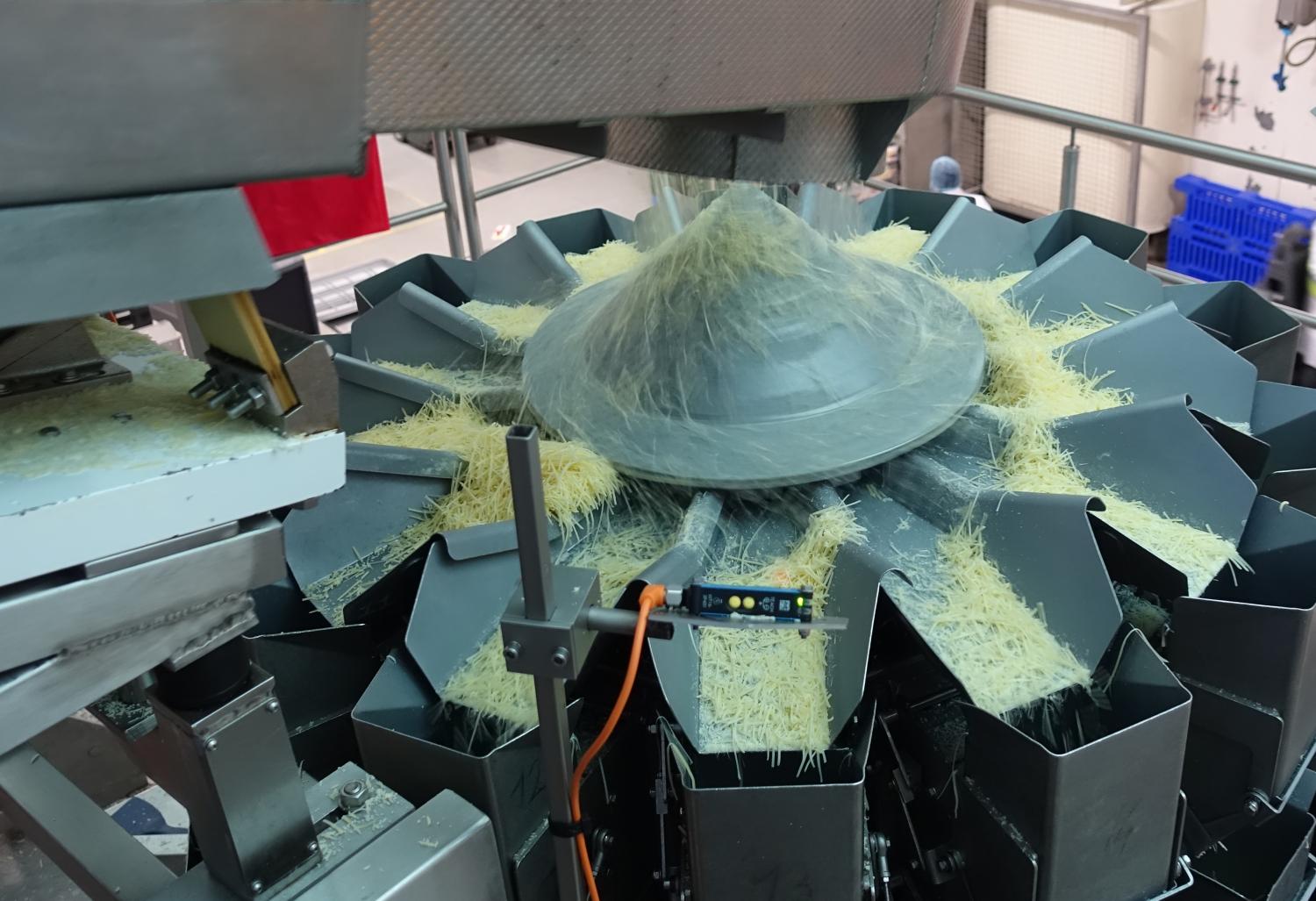

La Lorraine Bakery Group is a Belgian family company with more than 80 years of experience in the bakery sector. In their factory in Erpe-Mere, donuts and baguettes roll off four production lines.

To guarantee optimal production, temperature, humidity and air quality must always remain within prescribed limits. Arcsom worked on an efficient automation of the HVAC system.

Solution

La Lorraine's HVAC system consists of 23 fresh-air groups, 20 of which have mixing units for heat recovery. They are distributed over the roof and provide air circulation in the building. Corridors and less critical areas are heated with FCUs (Fan Coil Units).

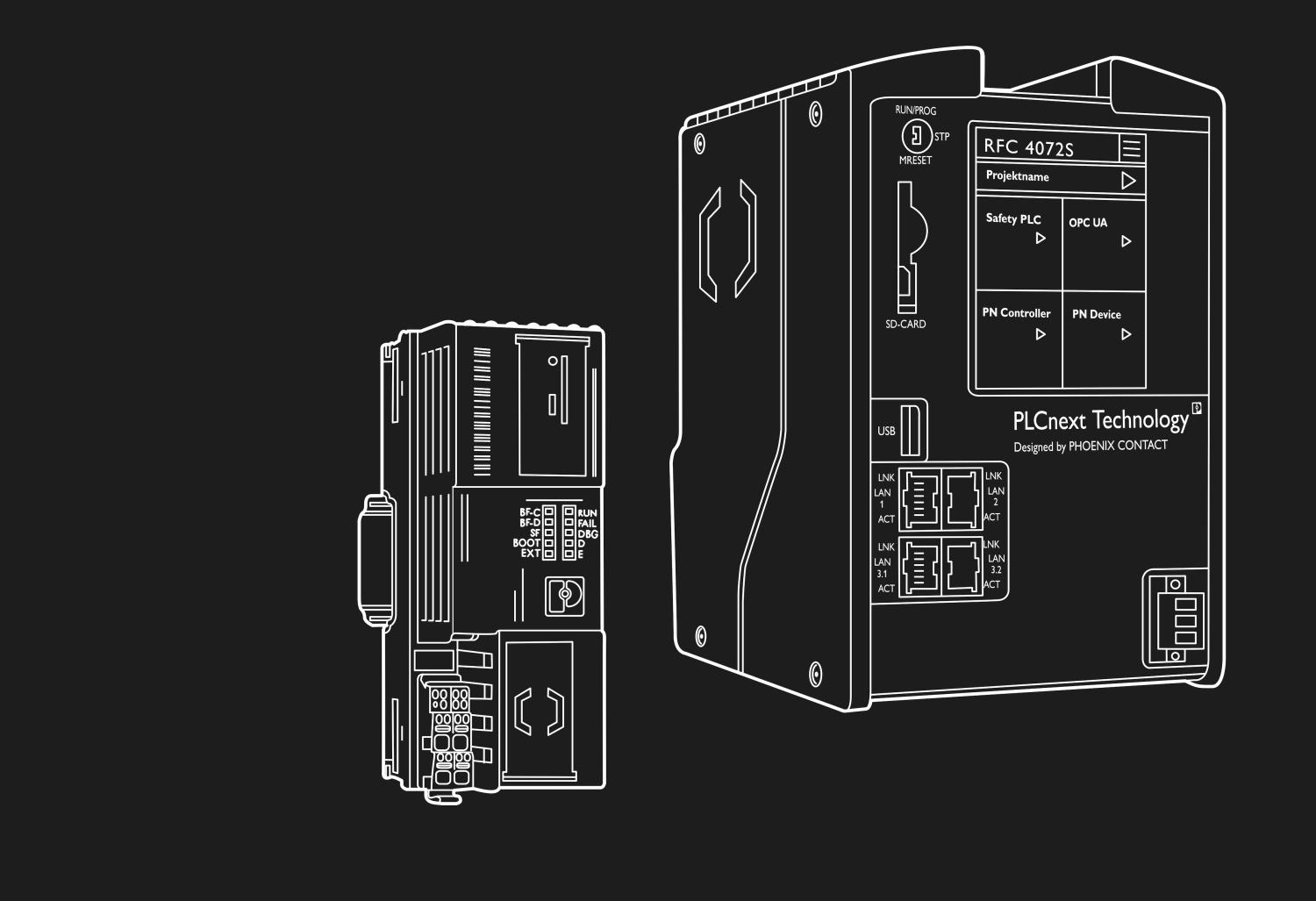

For a smooth start-up - and to reduce the number of cables - we install an electrical cabinet next to each air group with an I/O island, which communicates with the PLC via Profibus. Because of supply shortages due to the corona crisis, we use I/O islands from both Siemens and Phoenix.

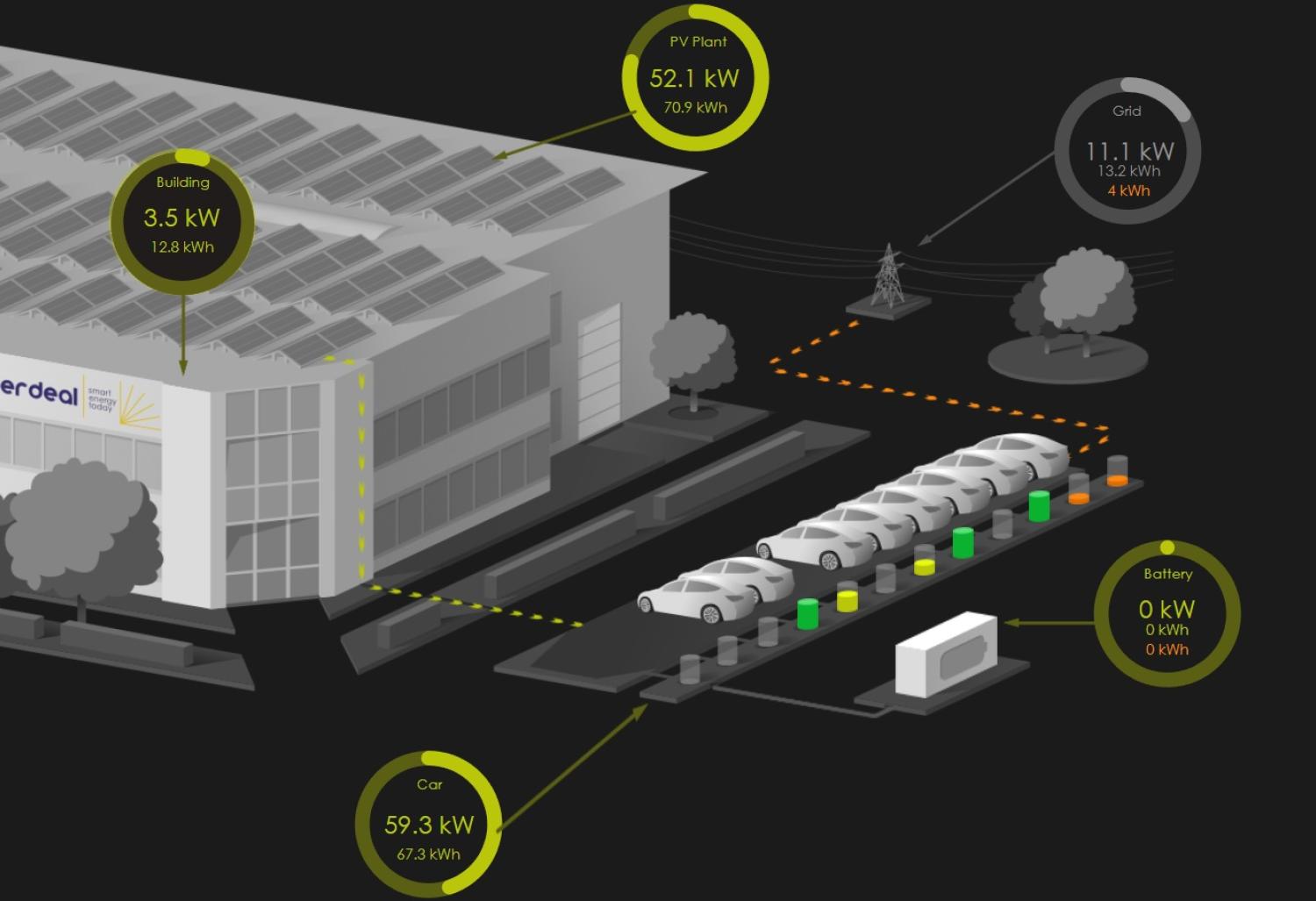

The entire HVAC system runs on 2 Siemens PLCs in the technical building, which also houses the central heating and sanitary buffer tank. Hot water is preheated with recovered heat from the Atlas Copco compressors that communicate with the PLCs via an Atlas Copco gateway.

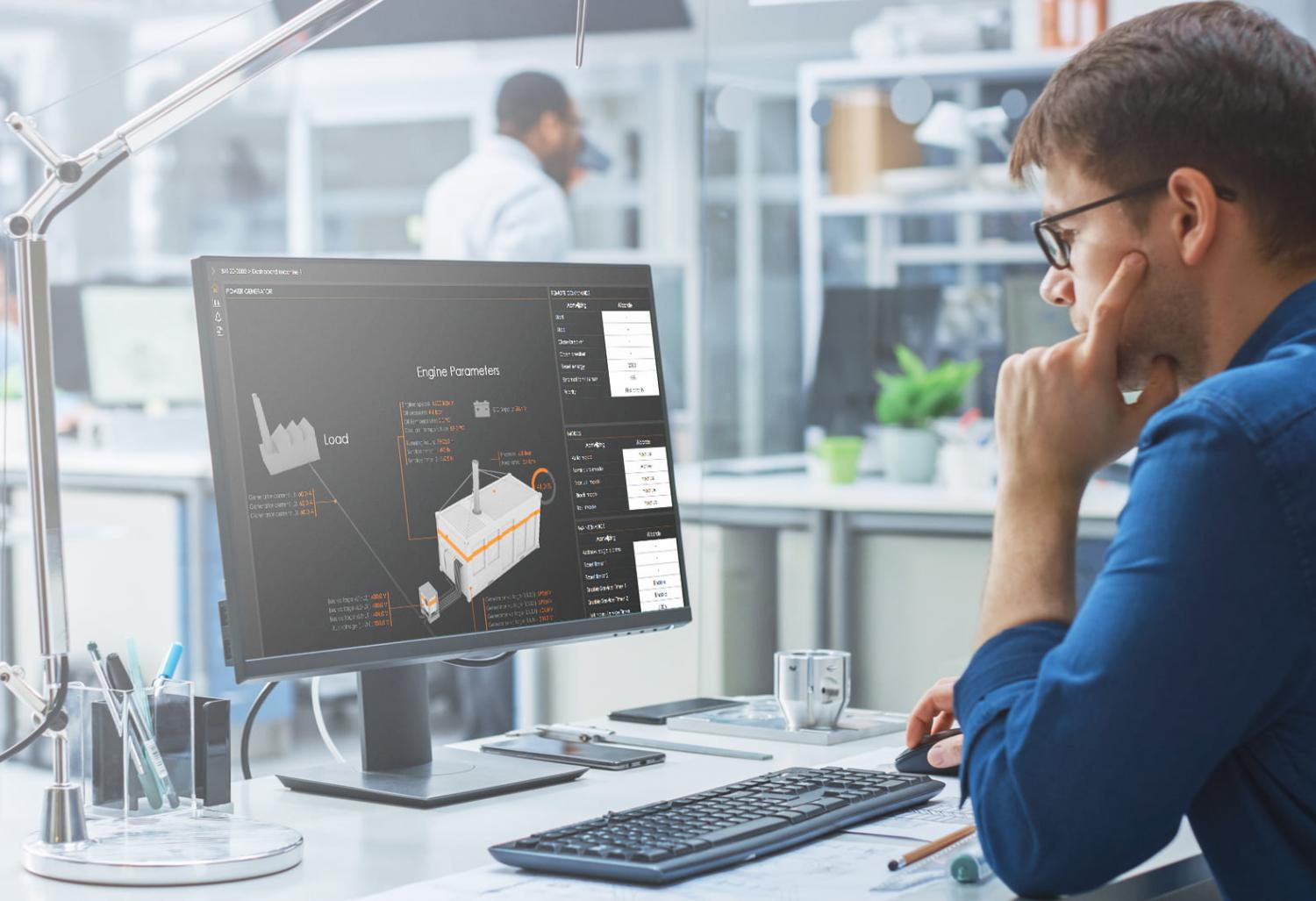

We optimise the operation of the sanitary buffer tank for maximum efficiency. Gas and water consumption are accurately measured and bundled into the PLC via a modbus gateway. This gives La Lorraine a clear overview of consumption in the HMI.

Each donut delivered by the production line has the perfect amount of chocolate. A precisely tuned heat exchanger ensures constant temperature and viscosity of the liquid chocolate.

“Arcsom programs an HVAC system for the 10,000 m² factory. A training course makes sure employees can now easily adjust parameters themselves to optimise the system.”

Kevin

Automation Engineer

Result

Perfect working conditions in a factory of more than 10,000 m². Clear overview of the plant’s HVAC operation.

Looking for a much-needed boost in your production? In an expert session, an Arcsom automation engineer will analyse your challenge. Request your free demo and take your first step towards a solution.