The challenge

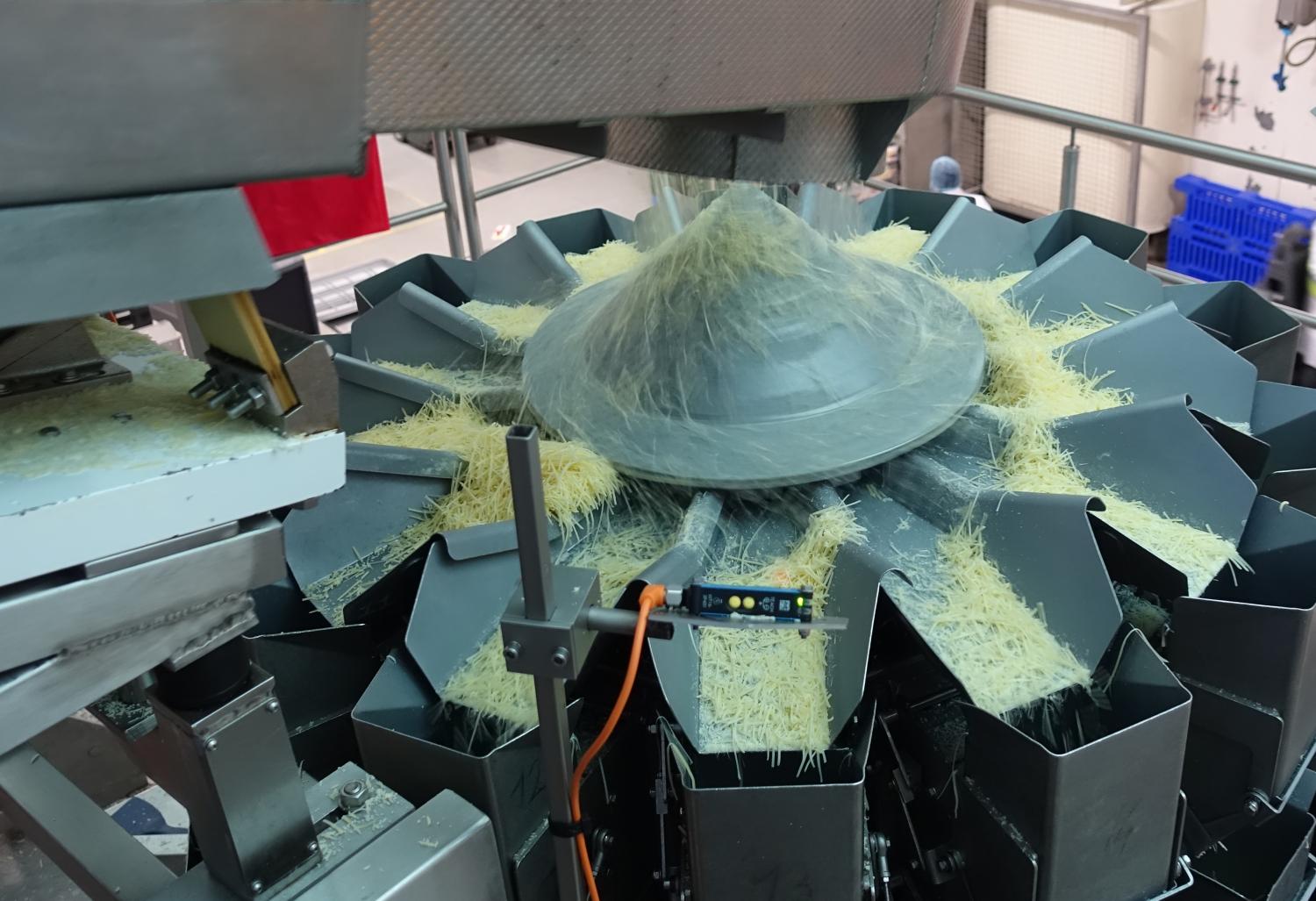

Thousands of crates filled with empties roll into Delhaize's distribution centre daily. Here, they get sorted and loaded onto palettes. Wholly automatically.

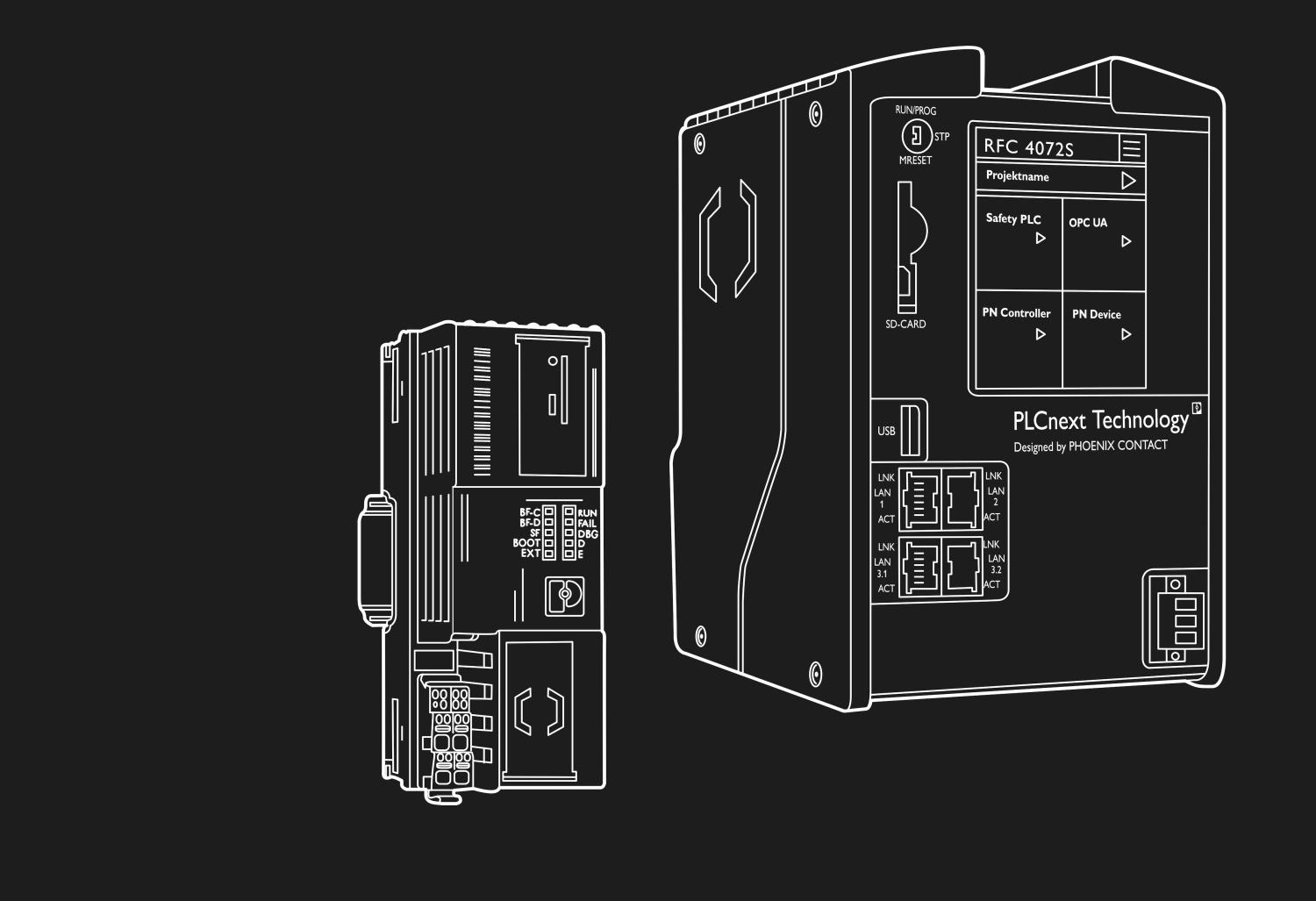

Or almost. The sorting line runs on obsolete PLCs and outdated software. The installation is therefore not always compatible with modern technology. Communication between the obsolete PLCs and the old control system is difficult. What should be an efficient automation process turns out to be time-consuming and error-prone.

Our solution

The installation gets a much-needed update. Arcsom optimises the process, with minimum downtime. This way, the flow of empties continues uninterrupted.

- With backups, we secure the old systems. Swift support guarantees continuous operation.

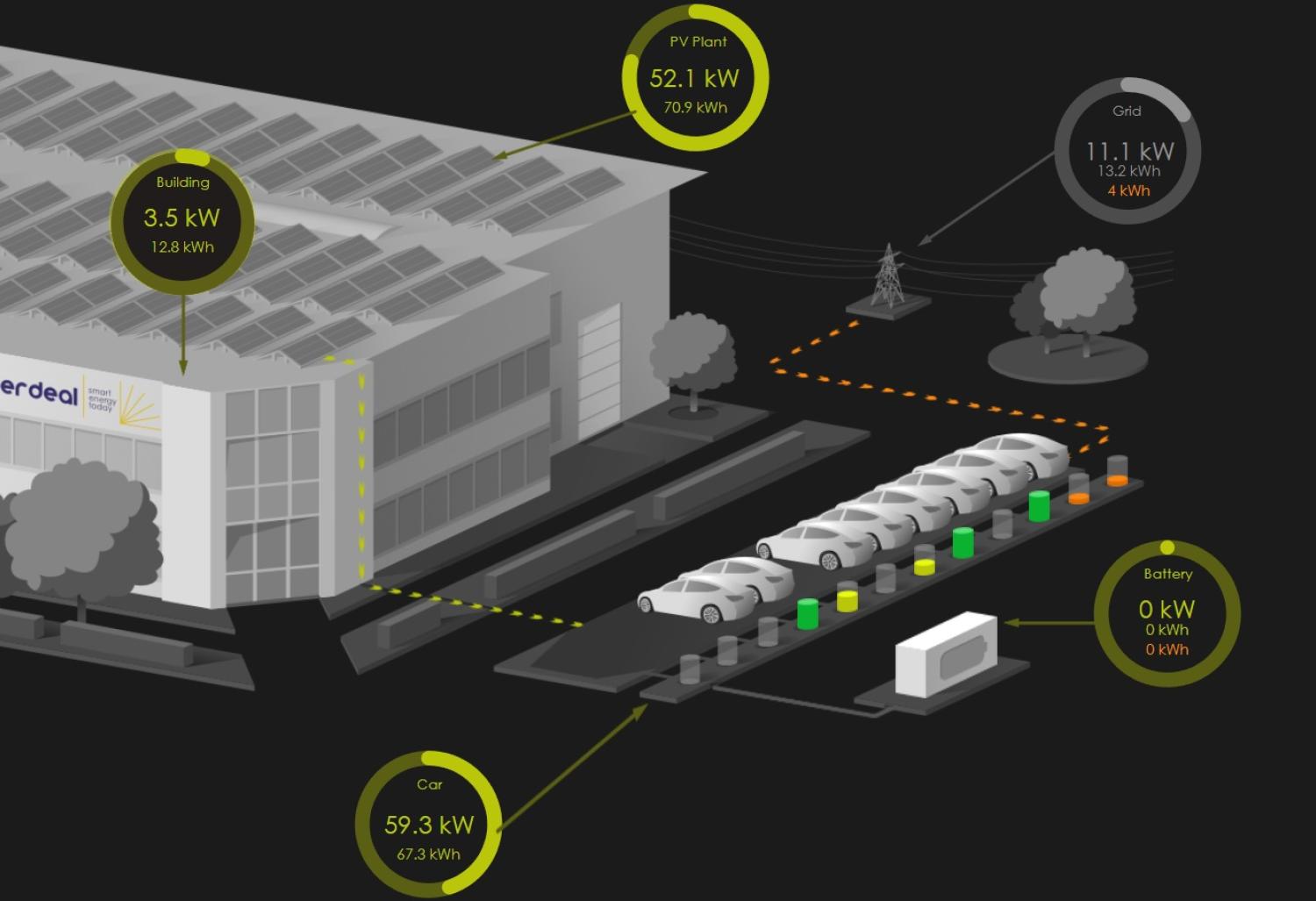

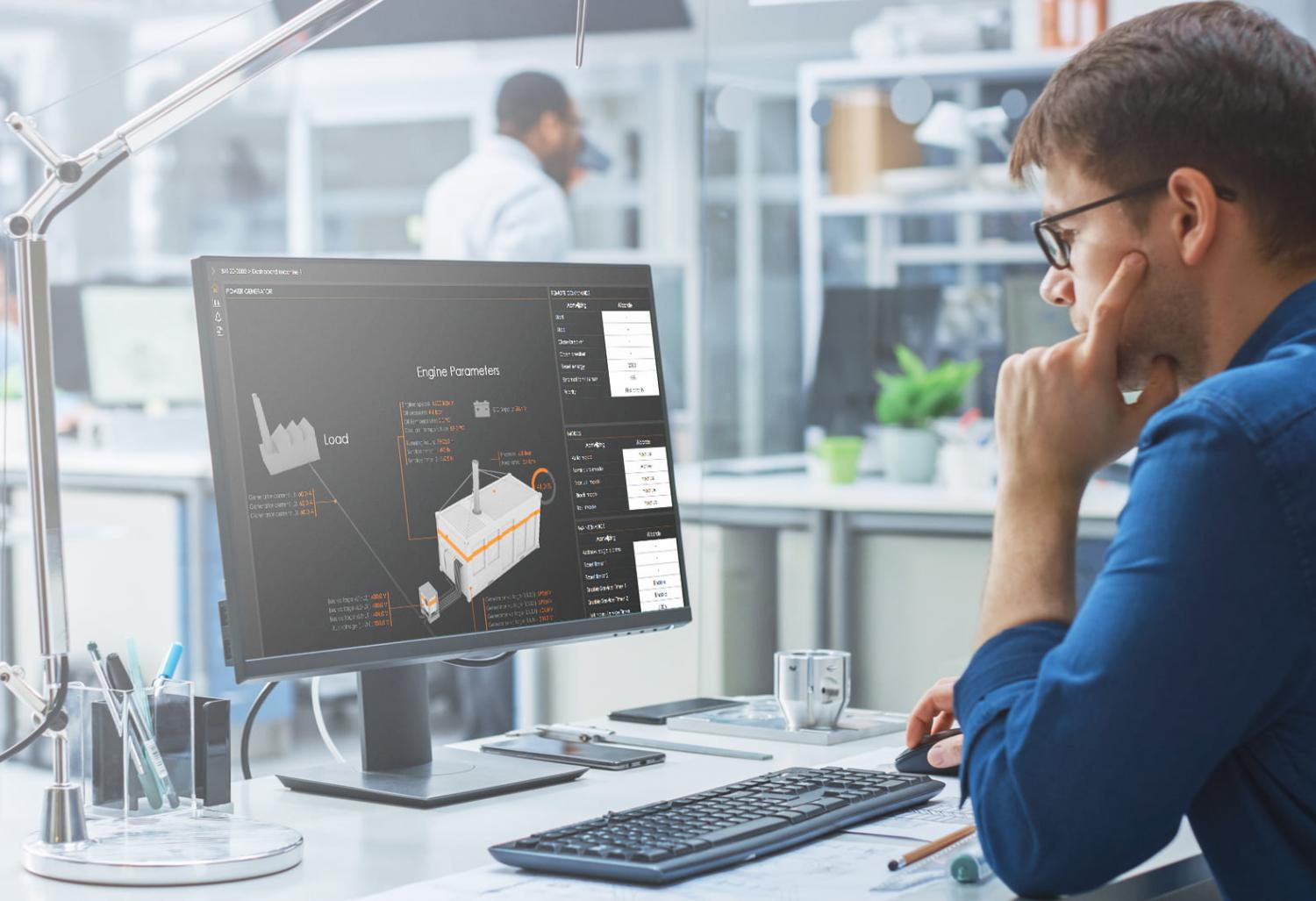

- A central supervision system (SCADA) monitors and controls the installation. The performance of the sorting line is monitored in real time so that problems can be addressed immediately. Some new functionalities even boost the processing of empty cases.

- Different modules in the automation process can now be operated separately. This makes maintenance easier.

- A smart reporting tool generates detailed reports on the performance of the sorting line. These reports are useful for further fine-tuning the process.

“With modern software and support for old hardware, Delhaize can get to work with a future-proof installation.”

Arne

Modernisation Solution Manager

The result

- The sorting line runs smoothly with updated PLCs and software.

- Delhaize constantly has its finger on the pulse, enabling them to analyse and adjust the entire process efficiently.

- With modern software and support for old hardware, Delhaize can get to work with a future-proof installation.

Is your installation running on old PLCs? It doesn't necessarily need to be boxed up. Arcsom brings continuity to your existing systems with unique expertise in obsolete PLCs.

Choose a sustainable and investment-friendly alternative to a complete hardware renewal.